I am growing up at Beihang Univeristy as a graduate student now in Beijing, China.

Currently, my main research interest is machine vision, based on a background in mechanical engineering. If you have any idea that you want to contact me after reviewing my homepage, I would be more than happy to receive your letter. Of course, discussing life with me is also a good choice. In fact, I am very eager to meet like-minded friends.

🔥 News

- 2024.05: I have officially started using and updating my academic homepage.

- 2024.05: 🎉 I am certain to pursue a PhD at Shanghai Jiao Tong University.

- 2024.04: 🎉 The paper is accepted by International Journal of Heat and Mass Transfer.

- 2024.04: 🎉 The paper is accepted by Engineering Applications of Artificial Intelligence.

- 2023.12: 🎉 The paper is accepted by IEEE Sensors Journal.

📖 Educations

- 2025.09 - 0000.00, Ph.D, the School of Mechanical Engineering, Shanghai Jiao Tong University, Shanghai.

- 2022.09 - 2025.06, Master, the School of Mechanical Engineering and Automation, Beihang University, Beijing.

- 2018.09 - 2022.06, Undergraduate, the School of Mechanical Engineering, Hebei University of Technology, Tianjin.

📝 Publications

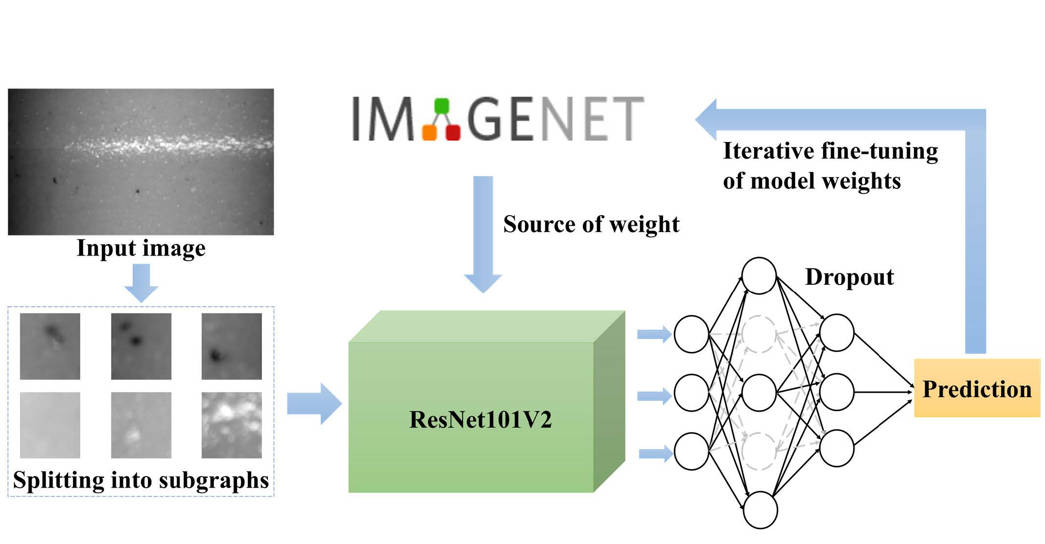

Detection of Defects in Adhesive Coating Based on

Machine Vision

Dong Guotao, Hanjun Gao, Qiong Wu*, et.al.

- A machine vision detection method for detecting adhesive coating defects after lining spraying has been proposed.

- The problem of coating integrity under high aspect ratio and unstable lighting conditions has been effectively resolved .

- In the design of the hardware system, full consideration has been given to the deflection compensation of the detection equipment

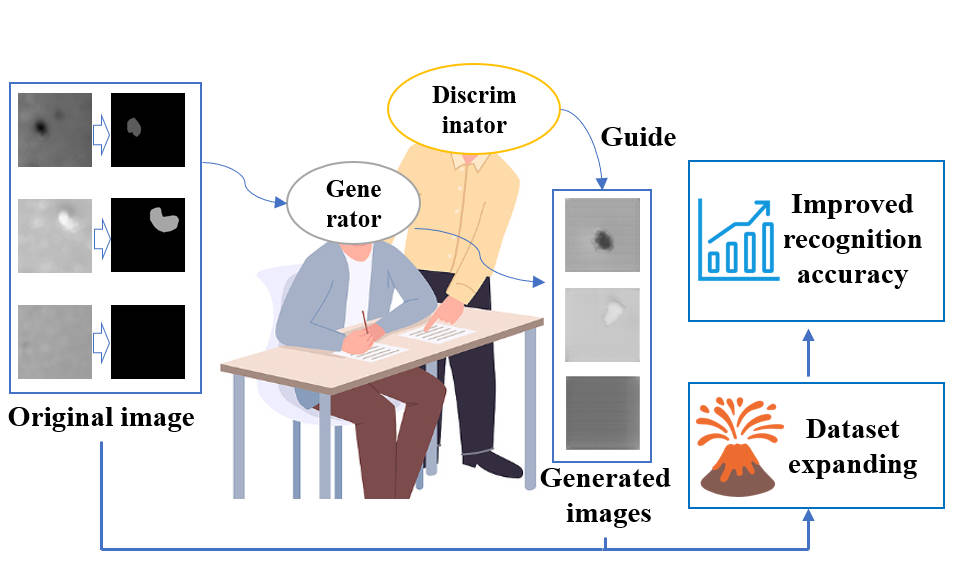

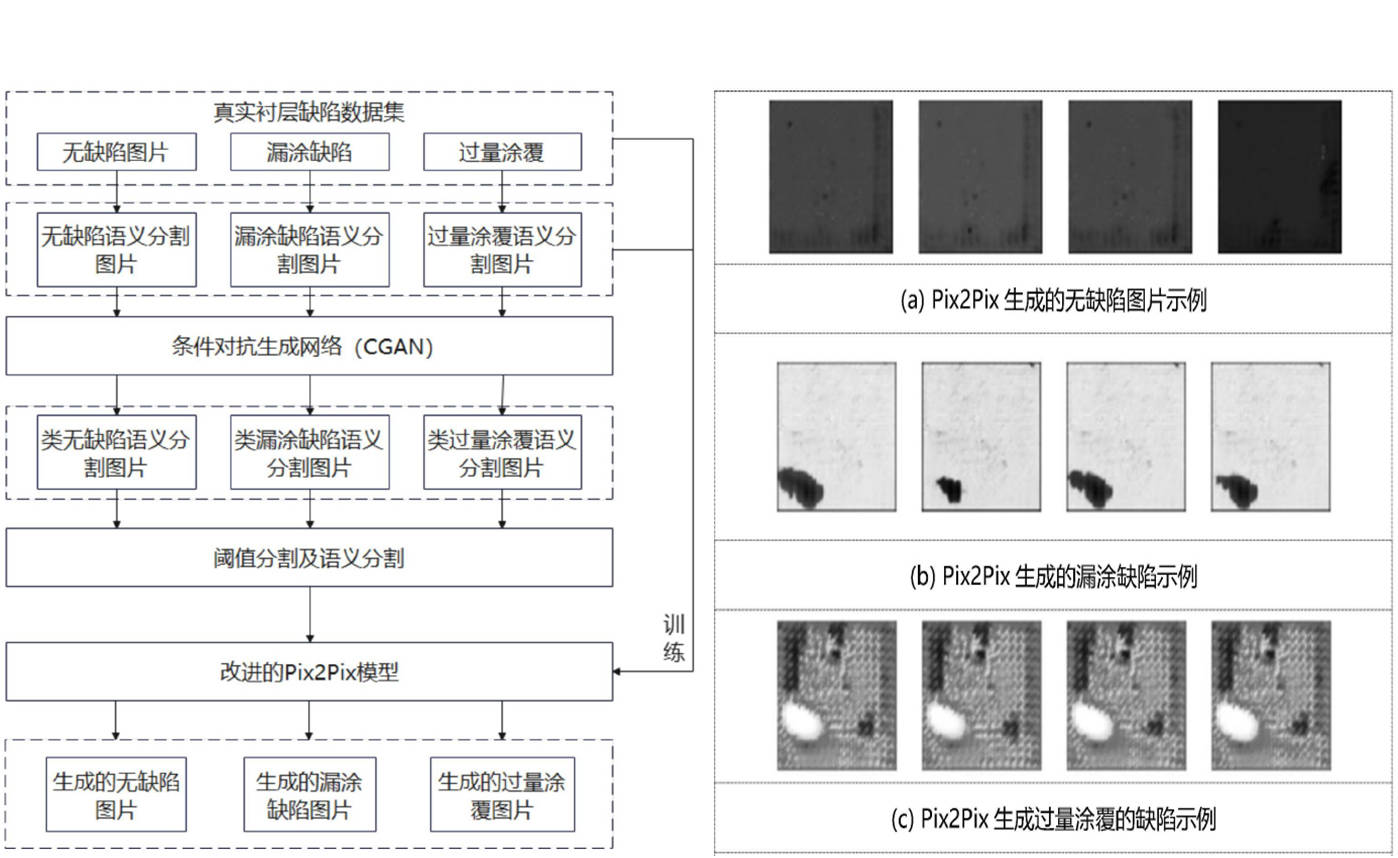

Expanding the Defect Image Dataset of

Composite Material Coating with Enhanced Image-to-image Translation

Dong Guotao, Hanjun Gao*, Kai Yang, Qiong Wu.

- A method named E-Pix2Pix has been proposed to enhance the defect image dataset of composite coatings in solid rocket engines.

- The depth research has been conducted on the influence of parameters during the image generation process.

- The impact of generating image content on classification models has been studied, and the potential negative impact is discussed.

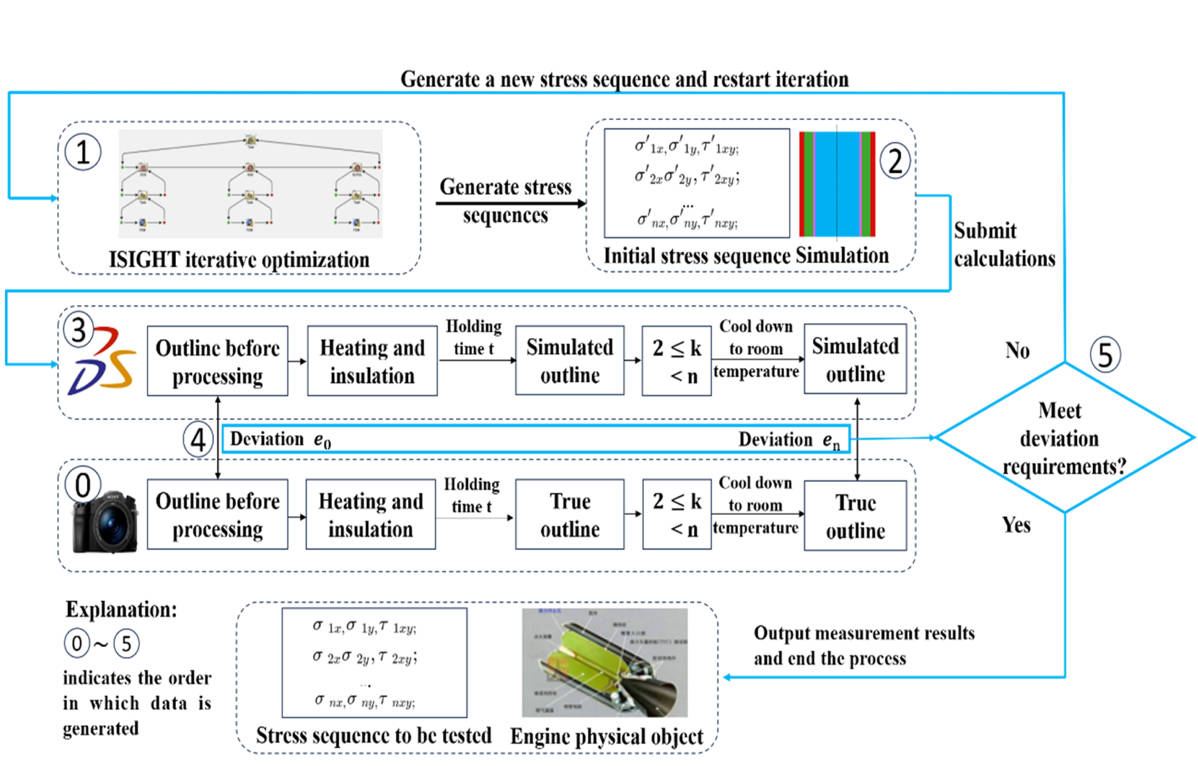

Formation Mechanism and Evolution of

Interfacial Residual Stress between Composite Propellant and Rubber Liner during Curing

Process

Hanjun Gao, Dong Guotao , Hao Yuan, et.al.

- A finite element model has been established to simulate the stress changes throughout the curing process.

- A vision based device has been designed to monitor deformation changes during the curing process.

- The detected deformation is combined with the simulation results to optimize the key parameters of the simulation in order to achieve accurate stress assessment.

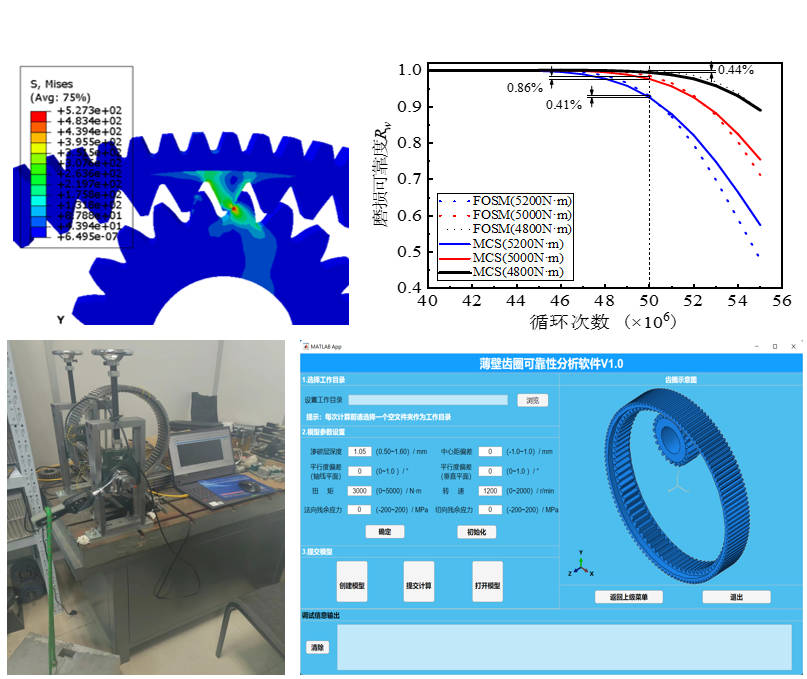

Analyze the Influence of Carburized Layer Thickness and

Assembly Error on the Reliability of Thin-walled Gear Ring System based on ABAQUS

Dong Guotao , Jing Guo, Minghui Lin, et al.

- Parametric modeling technology to establish a three-dimensional model for the gear ring system

- Finite element analysis and solution of various assembly errors that may occur during gear assembly process.

- Evaluate the performance of gear rings under different carburization layer thicknesses.

- A software based on Abaqus secondary development has been designed to achieve parameterized finite element simulation

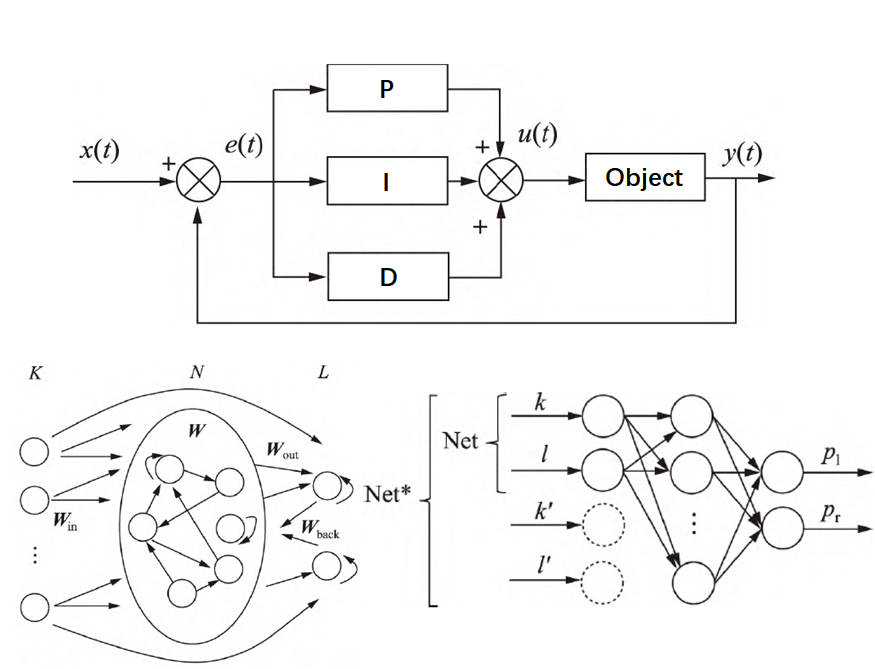

Review of Control Strategy for Steady

Movement of Pneumatic Manipulator

Dong Guotao, Chunyan Gao*, Xuan Chen, et al.

- A review has been conducted on three directions: fuzzy control, neural network control, and robust control.

- Fuzzy control and neural network control have developed rapidly and achieved good integration with other control theories. However, the development of robust control is slow and its application is limited.

- Based on existing research results, it is expected that the stable motion control strategy of pneumatic robotic arms will continue to develop along the trend of integrating and supplementing control theories.

Patent Name: A Machine-vision-based Creep Deformation Detection Device for Complex Components

Inventor: Hanjun Gao,Dong Guotao, Kun Yan, et al.

- Public account: CN117890205A

- The present invention provides a machine vision based creep deformation detection device for complex components, which can monitor the creep deformation of complex components throughout the entire process while ensuring the heat treatment effect, providing reliable data for exploring the creep evolution law of complex components.

Patent Name: A method for expanding the composite material coating defect dataset based on improved Pix2Pix

Inventor: Hanjun Gao,Dong Guotao, Qiong Wu, et al.

- Public account: CN117079752A

- The attention mechanism is introduced to improve the performance of the generator. The discriminator is designed to evaluate the generated defect sample images. The adversarial control design of the generator and discriminator is used to balance the abilities of the generator and discriminator, enabling the generator to better generate images containing defect features. Through the present invention, the problem of small and uneven sample sizes in defect recognition tasks has been solved.

🎖 Honors and Awards

- 2023.09 The First Prize Scholarship in Beihang Univeristy

- 2022.09 Top Grade Scholarship for graduate freshmen in Beihang Univeristy

- 2022.06 Outstanding undergraduate graduates in Hebei Province

- 2022.06 Outstanding Graduates from Hebei University of Technology

- 2022.04 Beijing Jingdiao Technology Enterprise Scholarship

- 2021.10 The 8th China TRIZ Cup College Student Innovation Method Competition (National Third Prize)

🤟 Friends

- book(A doctoral supervisor from the School of Mechanical Engineering at Shanghai Jiao Tong University)

- music(A professor and doctoral supervisor at Hebei University of Technology.)

- science(A master student in Northeastern University. Focusing on Application of machine learning, shield Intelligence.)

- others(A master student in the National Key Lab of Robotics and Systems. Focusing on robot autonomous operation technology.)